ZnSe Windows —USA CVD ZnSe

Choose high-quality imported crystal materials, which can withstand high-power lasers.

The double-sided coating is firm, wipe-resistant, not easy to fall off, and has a long service life.

High-precision processing, first use an excellent substrate, through cutting, polishing, coating and other processes to form a total.

High optical performance, high transmittance above 99.5%.

Product Details

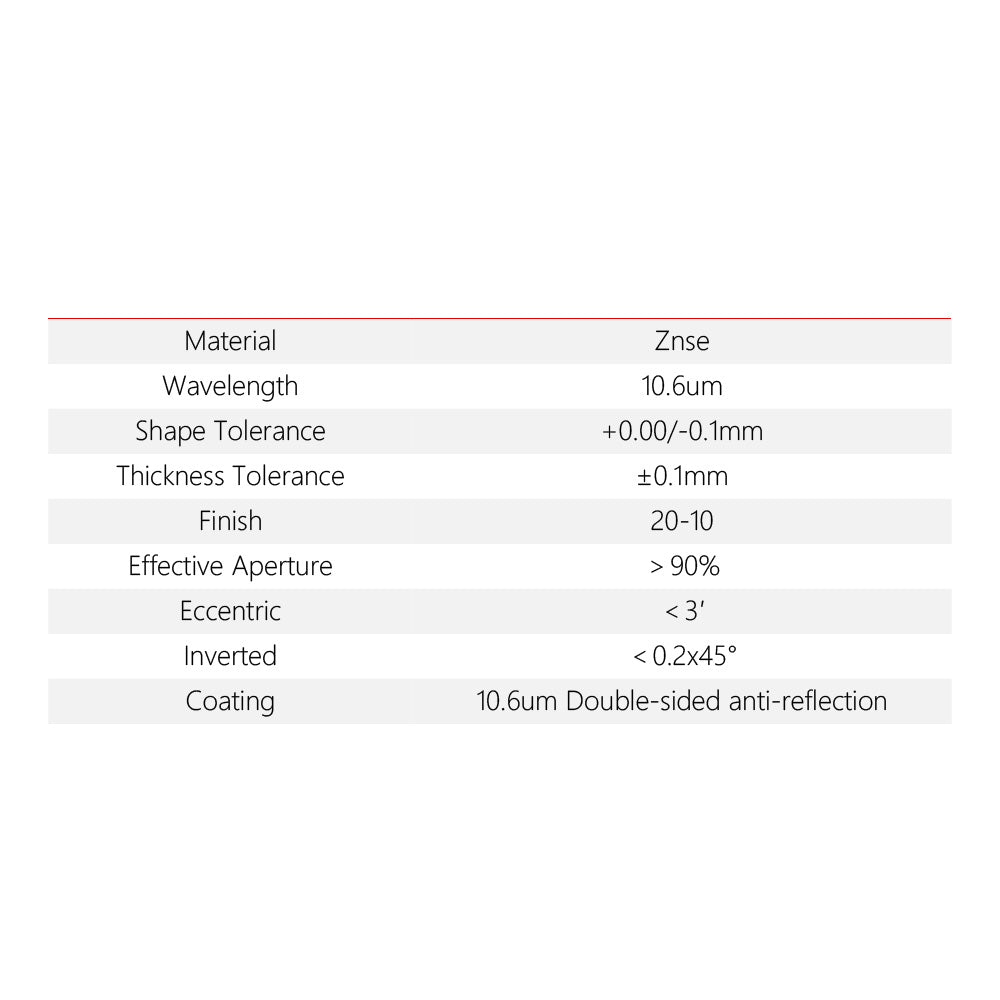

Material |

Znse |

Wavelength |

10.6um |

Shape Tolerance |

+0.00/-0.1mm |

Thickness Tolerance |

±0.1mm |

Finish |

10月20日 |

Effective Aperture |

>90% |

Eccentric |

<3′ |

Inverted |

<0.2×45° |

Coating |

10.6um Double-sided anti-reflection |

Specifications

Material |

Diameter |

Thickness |

Coating |

CVD ZnSe |

12.7 |

2.4 |

AR/AR 10.6um |

CVD ZnSe |

12.7 |

2.5 |

AR/AR 10.6um |

CVD ZnSe |

19.05 |

2 |

AR/AR 10.6um |

CVD ZnSe |

20 |

2 |

AR/AR 10.6um |

CVD ZnSe |

20 |

3 |

AR/AR 10.6um |

CVD ZnSe |

25 |

3 |

AR/AR 10.6um |

CVD ZnSe |

38.1 |

3 |

AR/AR 10.6um |

Cleaning instruction

1.Use an air bulb to blow off any loose contaminants. (dust, lint particles)

2. Squeeze a few drops of acetone onto the lens tissue, wetting the complete optic’s diameter. (smudges, fingerprints)

3. Using the cotton swab and distilled vinegar, wipe the lens. Immediately use a wet cotton swab to remove any acetic acid, then clean with a clean dry cotton swab. (spittle, oils)

Reviews

There are no reviews yet.